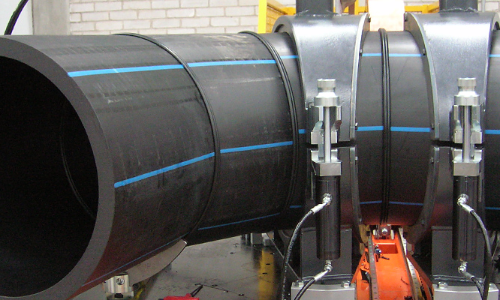

HDPE Jointing

This technique is used for welding pipes made from materials such as PE, PP, and PVDF. The process involves mounting the pipes in the clamps of the butt fusion equipment and ensuring proper initial alignment. The pipe ends are then planed to ensure they are flat and square, preparing them for the welding sequence.

The welding process begins when a flat heated plate is positioned between the two pipe ends. The pipes are pushed towards each other until they come into contact with the hot plate, and the pressure is increased to ensure good thermal contact. This causes the pipe ends to melt, and the interface pressure forces the molten material outward, forming 'weld beads' on the outside and inside pipe surfaces. This stage is referred to as the 'bead-up' stage.

Next, the pressure is reduced to a level sufficient to maintain contact between the pipe ends and the hot plate. This allows the melt depth to increase without enlarging the weld beads, a phase known as the 'heat soak' stage. At the end of this stage, the pipe ends are pulled away from the hot plate, which is then removed. The two molten pipe ends are pushed together at the same pressure used during the initial bead-up stage, causing further growth of the weld bead in a process called the 'bead roll over' stage. The pressure is maintained until the weld is fully cooled, and the joint is ready for use.

Key Features of HDPE Jointing

- Suitable for PE, PP, and PVDF pipes

- Ensures strong, leak-proof joints

- Highly reliable for industrial applications

- Performed by trained and certified technicians

Applications

HDPE jointing is widely used in various industries for creating durable and high-quality pipe joints. Common applications include:

- Water supply systems

- Gas distribution networks

- Industrial piping systems

- Chemical processing plants